Our vision is to improve yours – Meet the co-founders

Niko Eiden

CEO & Co-Founder

IXI started with a pause.

In 2021, Wili Miettinen and I had just stepped away from Varjo, the mixed reality company we co-founded, now recognized globally for creating the most advanced VR headsets in the world. We hadn’t planned our next move, but we saw something we couldn't ignore.

Both of us had spent our careers working on things that pushed the edges of what technology could do—and where it could go next. Wili, already a legend in Finland’s algorithm scene, had co-founded Hybrid Graphics, which NVIDIA acquired in 2006. He became one of their Principal Engineers and helped pioneer real-time 3D graphics long before it became mainstream. Since then, he’s founded and advised some of Finland’s most iconic deep tech startups.

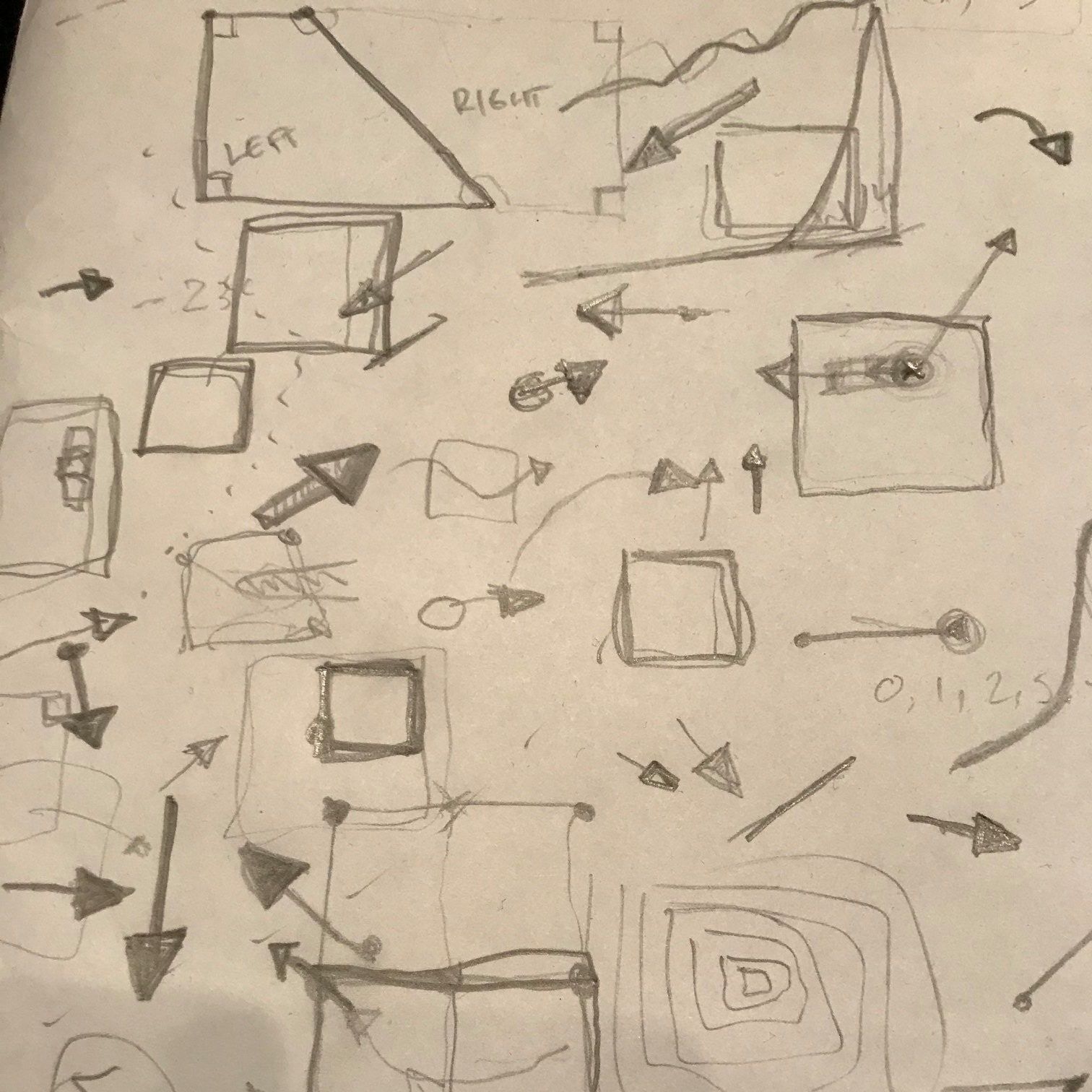

But Wili isn’t driven by titles or recognition. What fuels him is a kind of restless curiosity. A need to crack problems others consider impossible. He’s not satisfied until he’s understood something from every angle. He’s the kind of person who wakes up in the middle of the night to sketch a new mathematical model on whatever surface is nearby.

My own path started in mobile. I worked on some of the most iconic devices of their time, like the Nokia 3310 and 3315, which defined an era of global communication. At Nokia, I also contributed to early AR platform work that later became the foundation for Microsoft HoloLens. That same obsession with machine perception led me to AImotive, where I worked on machine learning and computer vision for automotive applications.

Eventually, I teamed up with Wili and others to start Varjo, where we built imaging systems that delivered human-eye resolution in virtual and mixed reality systems now used by leading astronauts and pilots. It taught us how to work across optics, imaging, and hardware to make the impossible real. Those same skills were soon directed toward a very different kind of challenge at IXI.

Optimal vision in every situation.

One concept that really fascinated Wili and me was liquid crystal optics. The idea that eyewear lenses could dynamically adapt, just like the human eye, sparked something in us. We were driven by a simple question: is this possible to build?

It came up again and again. We’ve always had a bit of reckless courage when it comes to taking on seemingly impossible challenges. In fact, when someone says, “this can’t be done”, that’s usually when we lean in.

At IXI, our mission is straightforward: to build eyewear that adapts in real time to how you see the world. Lenses that autofocus based on where you look: instantly, naturally, and without effort. Because seeing clearly shouldn’t require adjusting, switching, or squinting. It should just work.

It’s not magic, it’s a method.

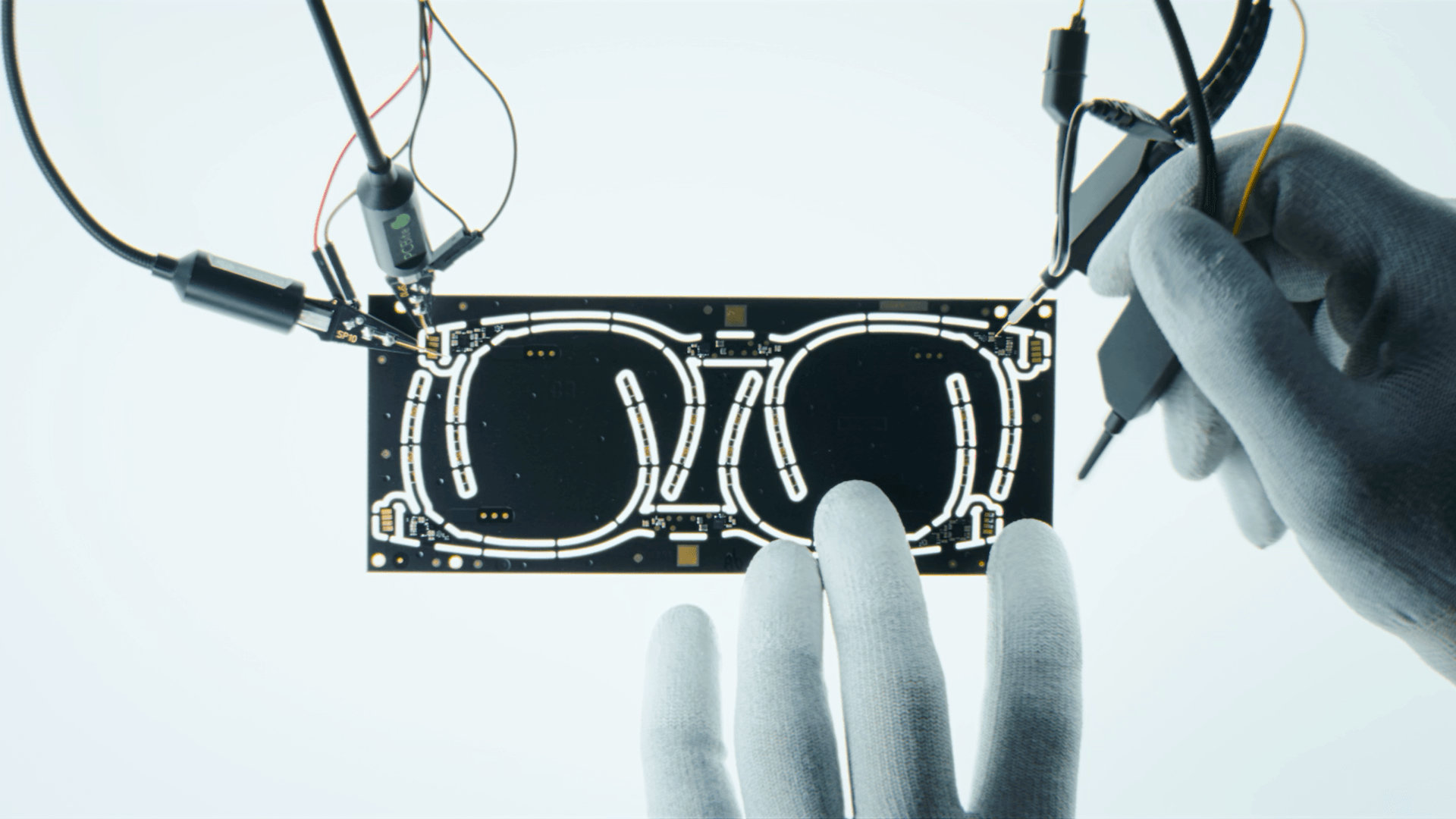

What we’re building is incredibly hard. Some have even called it impossible. Autofocus eyewear powered by real-time gaze tracking, liquid crystal optics, and ultra-low-power computing is something even the largest players in tech have struggled to make real. The fact that we’ve come this far is something we’re proud of, but we know that progress doesn’t come from a single breakthrough. It comes from how you solve problems — again and again.

That mindset is baked into our culture. We’ve brought together people who thrive on complexity. Wili and I have both spent our careers going deep into specific domains: mobile/telco, graphics, optics, imaging, machine learning. One bubble at a time. That kind of focus, repeated over time, builds real range. It creates a mental map you can draw on across disciplines. And when we hit a wall, especially in algorithm development, that’s when the method kicks in: map every possible path, build a taxonomy of solutions, work through them one by one. No shortcuts. No guesswork. Just structure, intuition, and a deep respect for the problem itself.

We also hold to a core principle: we don’t outsource the hard parts. That’s non-negotiable. To move fast and build something truly new, we need to understand every detail of what we’re making. That often means building the tools ourselves. It’s not about control. It’s about clarity. When you work with your own hands, you understand where the limits are and how to push past them.

Designing technology that disappears.

From day one, we’ve challenged a basic assumption in consumer tech: that big impact requires big presence. We believe the opposite. Technology shouldn’t be bulky, distracting, or uncomfortable. The most transformative products are the ones that disappear into daily life. They feel natural, look familiar, and work so well you forget they’re even there.

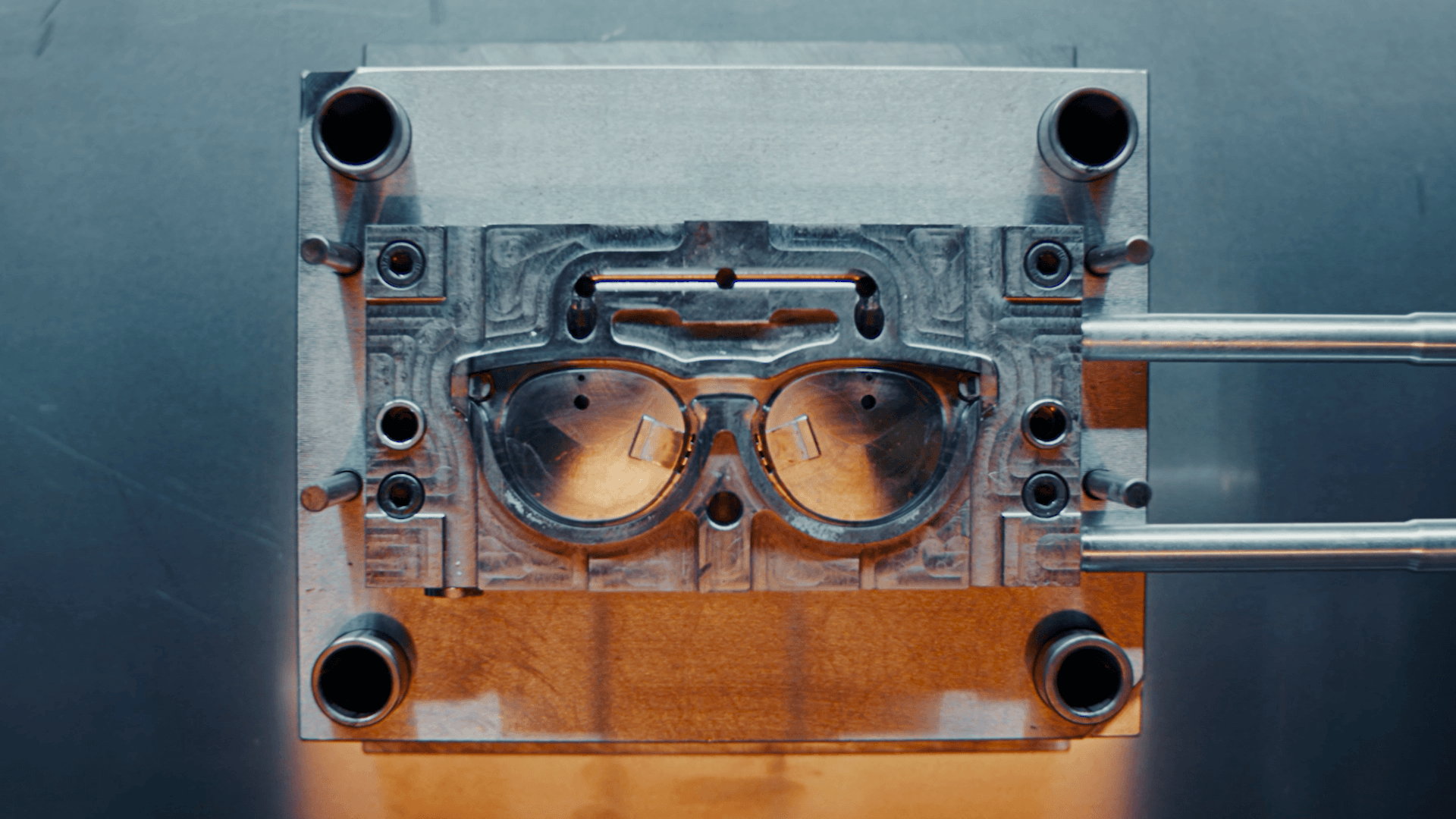

That’s why we care deeply about how our technology is experienced—what we call consumer acceptance. It’s not just about whether the technology is functional. It’s about whether people want to wear it every day. Does it feel familiar? Comfortable? Desirable? Autofocus glasses shouldn’t just match traditional eyewear in comfort. They should surpass it. They should feel lighter, more intuitive. Like they’ve always belonged on your face.

That’s a huge design challenge. The space we have to work with is smaller than anything the smart eyewear world has dealt with. We don’t have room for bulky processors or off-the-shelf eye-tracking modules. So we’ve had to invent completely new methods to miniaturize electronics. Systems powerful enough to deliver real-time performance, but small enough to disappear into the frame.

And through it all, we keep coming back to one question: What should vision correction feel like five years from now? Our answer is still the same. It shouldn’t feel like anything. That’s the standard we’re working toward.

And we won’t stop until it becomes reality.